PRODUCTION

COMPLEX PART MANUFACTURING

In complex part manufacturing, the first geometries that come to mind are compressor impellers and turbine blades. Thanks to our simultaneous 5-axis CNC machines, we are able to manufacture them with high precision.

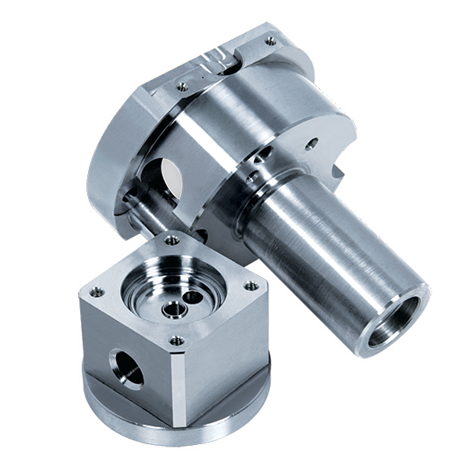

MULTI-OPERATION MACHINING

Turning, milling, drilling, tapping and deep hole drilling operations can be performed on a single CNC machine instead of multiple machines. This allows us to achieve highly precise geometric tolerances.

THIN-WALLED PARTS AT COMPLEX ANGLES

We utilize the latest innovative technologies to machine complex angles with maximum precision and manufacture thin-walled parts with tight tolerances and advanced fixturing solutions.

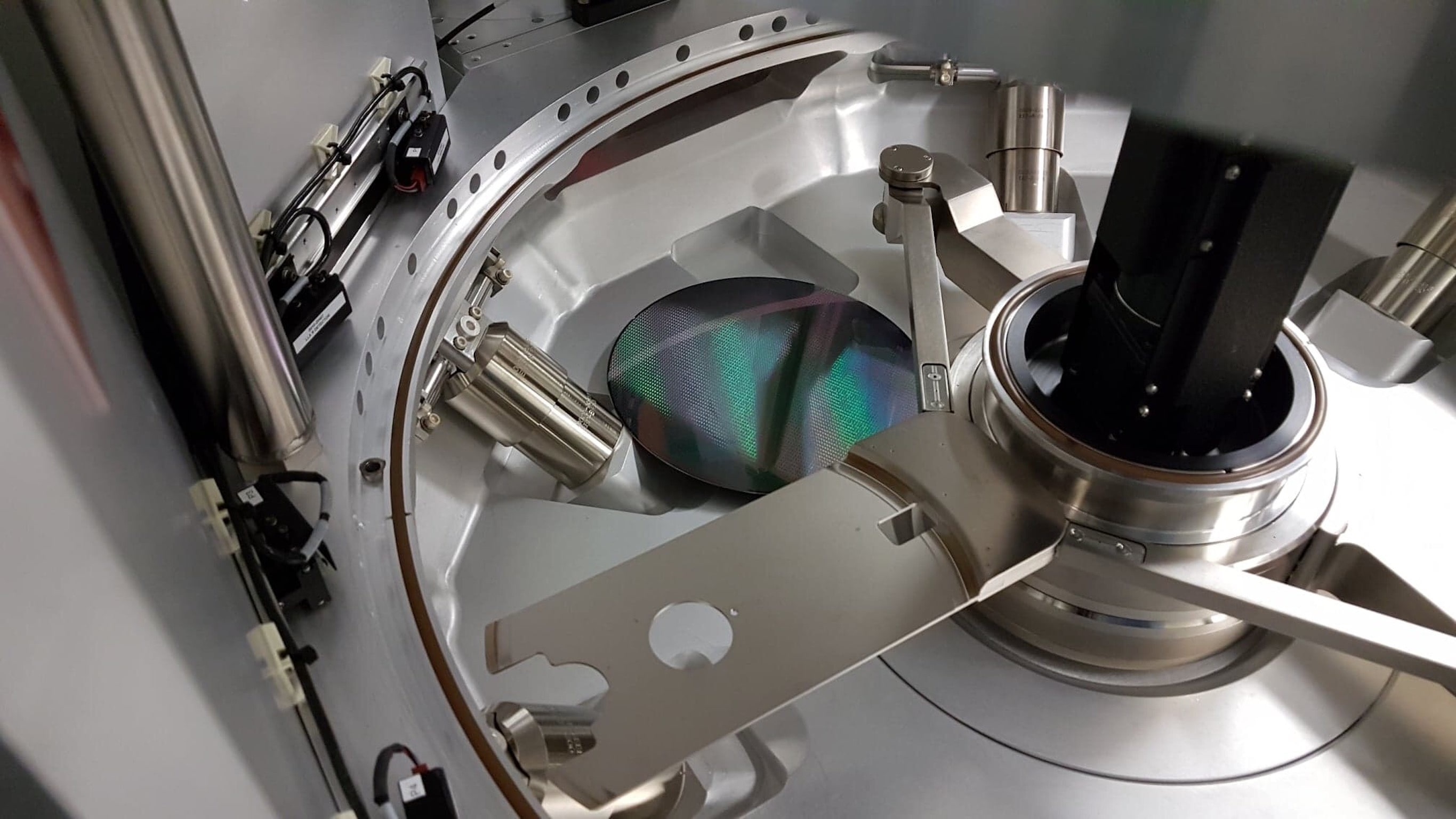

TITANIUM MACHINING

Manufacturing titanium parts for special applications is one of the greatest challenges in machining. ASGENA can customize and produce titanium components for all your aerospace and defense needs.

CUSTOM GEAR SHAFT MANUFACTURING

We manufacture precision gear shafts for automotive, motorsports, railway, aerospace and petrochemical industries and provide prototype development through reverse engineering.

HIGH-VOLTAGE INSULATION COMPONENTS

We produce high-voltage insulation components for the energy and electrical industries, from development to mass production.

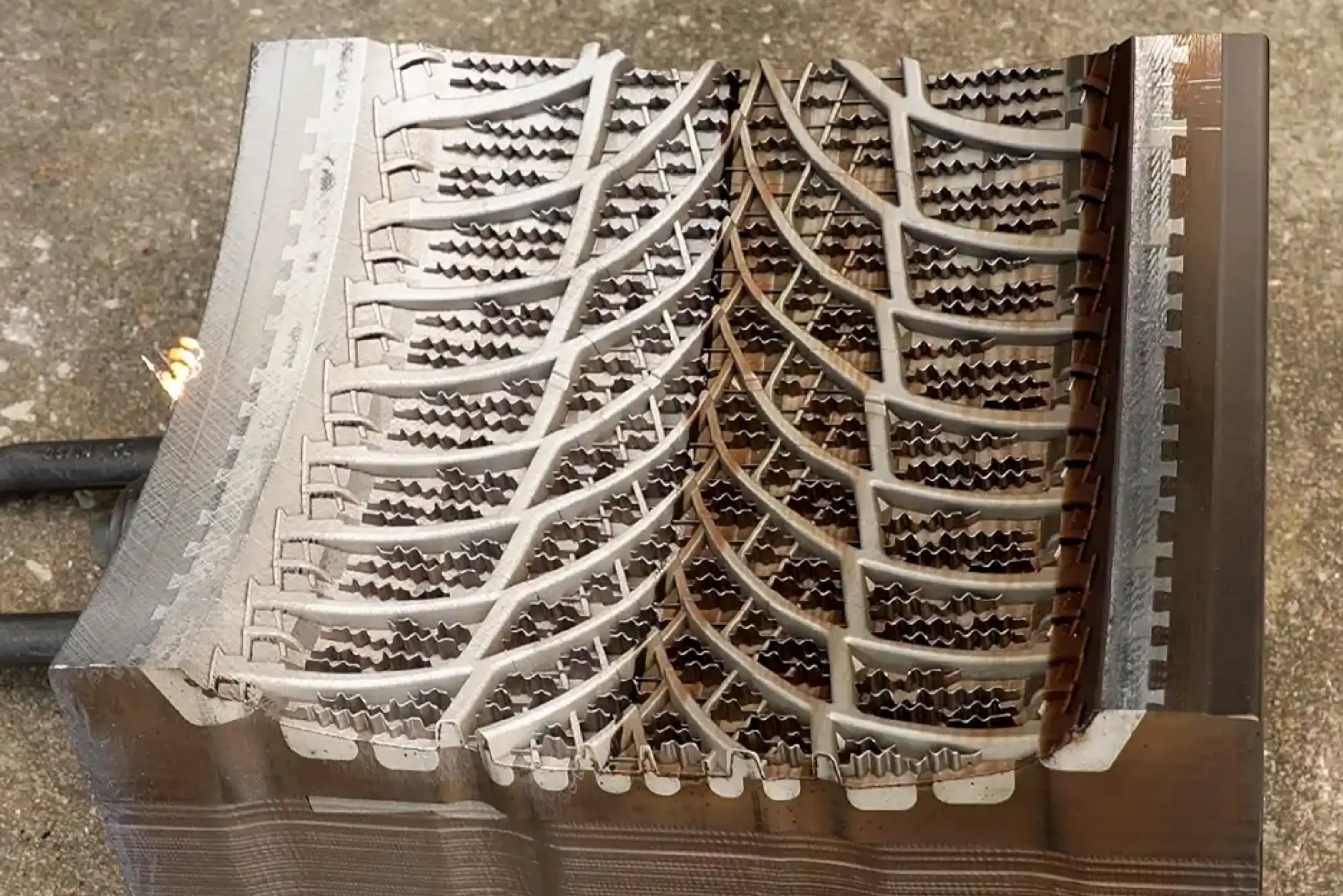

AUTOMOTIVE TIRE MOLD MANUFACTURING

We provide development and mass production services for custom-designed, high-precision tire molds for the automotive industry.